Bugs and Feature reqests

Hey guys,

is it possible to get more values at the parametric outputs?

is it possible to get more values at the parametric outputs?

Best regards,

Jan

Jan

Re: Bugs and Feature reqests

you can use virtual outputs and use them for parametric - when active virtual is 100 when not is 0Jan32 wrote:Hey guys,

is it possible to get more values at the parametric outputs?

Re: Bugs and Feature reqests

Hi guys, I use 1.141 right now.

BUG report:

The PWM output for BC seems to behave really odd. When no RPM and Ign on, the output still jumps from 0% to 100% rhytmically every ~2seconds.

But what costed me so muuuch time to figure out, even when the engine is running, a DC close to 100% (like 94%) leads to sometimes stochastically jumping to 0%!!! I always thought it was my boost actuator behaving irreproducable strange. But when I set max DC to 90%, so that there is enough space to 100%, and everything works as expected.

Generally, the DC of the boost output does not seem to be very accurate (not its resolution but its repeatability!). Its more like a probability of being at a certain DC...

Feature request:

would it be possible to make it decidable in the client if the Boost-Gear-Scale only affects the Base DC table?

Kind regards

Clem

BUG report:

The PWM output for BC seems to behave really odd. When no RPM and Ign on, the output still jumps from 0% to 100% rhytmically every ~2seconds.

But what costed me so muuuch time to figure out, even when the engine is running, a DC close to 100% (like 94%) leads to sometimes stochastically jumping to 0%!!! I always thought it was my boost actuator behaving irreproducable strange. But when I set max DC to 90%, so that there is enough space to 100%, and everything works as expected.

Generally, the DC of the boost output does not seem to be very accurate (not its resolution but its repeatability!). Its more like a probability of being at a certain DC...

Feature request:

would it be possible to make it decidable in the client if the Boost-Gear-Scale only affects the Base DC table?

Kind regards

Clem

Fuel Injector cleaning and flow measuring service needed? -> contact me :)

Re: Bugs and Feature reqests

What frequency do you use ?

Re: Bugs and Feature reqests

Hi Clem!

It is fixed in 1.146 but the min/max DC depends on frequency. For 400Hz the min DC is 6% the max dc is 94%

For 200Hz min is 3%, max is 97 and so on. It is hardware limitation.

For standard solenoids it is not a problem due to their nature.

It is fixed in 1.146 but the min/max DC depends on frequency. For 400Hz the min DC is 6% the max dc is 94%

For 200Hz min is 3%, max is 97 and so on. It is hardware limitation.

For standard solenoids it is not a problem due to their nature.

Re: Bugs and Feature reqests

Thanks! I will try it in a moment.

I use 400Hz, and analogize the pwm with a dual RC Lowpass filter.

Kind regards

Clem

I use 400Hz, and analogize the pwm with a dual RC Lowpass filter.

Kind regards

Clem

Fuel Injector cleaning and flow measuring service needed? -> contact me :)

Re: Bugs and Feature reqests

I think thats already possible, you have falling signal spacing 120,190,170,240

so try setting primary trigger to multitooth, number of teeth 3 and secondary trigger to falling edge and next edge rejection angle to about 210, (try different settings >190,<240 )

It should pick up the falling edge just after No1 TDC the rest you can do with first trigger tooth and the firing sequence start position etc.

so try setting primary trigger to multitooth, number of teeth 3 and secondary trigger to falling edge and next edge rejection angle to about 210, (try different settings >190,<240 )

It should pick up the falling edge just after No1 TDC the rest you can do with first trigger tooth and the firing sequence start position etc.

Re: Bugs and Feature reqests

Hi,

Unfortunately even after updating to the latest firmware/software, when importing log data from keelog, the Lambda/AFR target still shows as 0.00 and autotune always recommends a change of all boxes in the VE table to 0.0

Also, minor issue but the table sets now show as table 1 or 2 but the log still shows table 0 or 1 so in channels config, it only allows a maximum setting of 1....because of this a switch from table 1 to 2 and vice versa never shows in the log.

Regards,

Edward.

Unfortunately even after updating to the latest firmware/software, when importing log data from keelog, the Lambda/AFR target still shows as 0.00 and autotune always recommends a change of all boxes in the VE table to 0.0

Also, minor issue but the table sets now show as table 1 or 2 but the log still shows table 0 or 1 so in channels config, it only allows a maximum setting of 1....because of this a switch from table 1 to 2 and vice versa never shows in the log.

Regards,

Edward.

Jadzwin wrote:Tommorow there will be version 1.400. You should be able then to use Autotune.

Mobilelpg wrote:Is there any update on when the Keelog import data will include Lambda/AFR target?

Ever since I fitted the ECU I have an issue where everytime I rev to and above 5,000rpm my laptop freezes (tried numerous laptops and cables) so I am unable to datalog anything above 5,000rpm.

The Keelog grabs all data but Autotune can not be used as it does not recognise the required AFR/Lambda targets.

I would really like to enter the Keelog data into Autotune.

Thanks,

Edward.

Re: Bugs and Feature reqests

Thanks for the improvement! I am just curious, the fuel pump "primes" twice with the new version of firmware. Does the Emu now apply also two of the prime pulses?

Feature request, as I always encounter boost spike: is it possible to make the DC error correction 3D ? so that error correction is a little 6x6 table on boost error vs rpm?

When I adjust the error correction table for accelerating from low revvs giving no boost spike, quick accelerating from mid revs makes a big spike.

If I adjust for no spike in mid rev accelerations, there is crappy spoolup from low revs.

Thanks for your great support

kind regards Clem

Feature request, as I always encounter boost spike: is it possible to make the DC error correction 3D ? so that error correction is a little 6x6 table on boost error vs rpm?

When I adjust the error correction table for accelerating from low revvs giving no boost spike, quick accelerating from mid revs makes a big spike.

If I adjust for no spike in mid rev accelerations, there is crappy spoolup from low revs.

Thanks for your great support

kind regards Clem

Fuel Injector cleaning and flow measuring service needed? -> contact me :)

Re: Bugs and Feature reqests

Is it possible to add few more Aux OP's to the CAN expander box? or produce a dedicated OP expander?

I guess it would need its own external power ground but that should be no problem.

With stepper idle and VVT we very quickly run out of OP's for all the other auxiliaries

I guess it would need its own external power ground but that should be no problem.

With stepper idle and VVT we very quickly run out of OP's for all the other auxiliaries

Re: Bugs and Feature reqests

Hello guys,

yesterday I encountered a minor bug on version 1.146. The values for TPS and RPM in the tune display are jumping between 0 and the real value, while the values are rock stable in the Log/Basic window. When throttle is pushed a bit, the problem is gone. For RPM it is still there, independent of the current RPM value.

I have a feature request, too: Is it possible to let the user configure an analog Input to use it as EGT? It could be implemented like for AFR Input by letting the user define the EGT values for 0V and 5V and use a linear characteristic or like the tables for the IAT and CLT value. The latter would be even better. Background is that I have an external controller for my EGT probe with a display that I want to keep, but I also want the ECU to use the value for correction maps without installing another probe.

Another question: Is it possible to output the current injector DC as a PWM signal on another output than the actual injector outputs (due to noise on the inj. ouputs) for monitoring purpose? It would be easy, if the PWM #1 output setting included an option "inj DC" as X-Axis setting. Or is there another possibility already?

Thank you and keep up the great work!

Ralf

yesterday I encountered a minor bug on version 1.146. The values for TPS and RPM in the tune display are jumping between 0 and the real value, while the values are rock stable in the Log/Basic window. When throttle is pushed a bit, the problem is gone. For RPM it is still there, independent of the current RPM value.

I have a feature request, too: Is it possible to let the user configure an analog Input to use it as EGT? It could be implemented like for AFR Input by letting the user define the EGT values for 0V and 5V and use a linear characteristic or like the tables for the IAT and CLT value. The latter would be even better. Background is that I have an external controller for my EGT probe with a display that I want to keep, but I also want the ECU to use the value for correction maps without installing another probe.

Another question: Is it possible to output the current injector DC as a PWM signal on another output than the actual injector outputs (due to noise on the inj. ouputs) for monitoring purpose? It would be easy, if the PWM #1 output setting included an option "inj DC" as X-Axis setting. Or is there another possibility already?

Thank you and keep up the great work!

Ralf

Re: Bugs and Feature reqests

Hi Guys,

New EMU owner here from Australia.

Not sure if these things have been mentioned already, but a few feature requests for the software:

- Ability to change units(Load in PSI or KPa for example)

- A gauge for MGP (manifold gauge pressure) rather than MAP only

- Ability to use MGP value on the table load axis rather than MAP only

- Different gauge layouts, just simple text box type so they can be made smaller on the desktop page and still easily be read to grab value whilst tuning. This is a screen cap from my haltech layout and my NIStune layout, which I use 90% of the time I am tuning. The gauges are great on their own desktop, but I find them very hard to read in small size. This could also be done by making each gauge with a context menu that allow setting gauge type, for exmaple: Bar Gauge, Text Gauge, Dial Gauge, Graph Gauge etc... Then a propertied window where you could set warning values, colors etc.

- Min/Max values for each gauge, and when that threshold was met, the gauge would flash red or similar. Haltech software works this way and it is very handy for seeing when CLT for example is oevrheating on the dyno as the red flashing grabs attention. Same with Oil Pressure dropping below a minimum.

- Lastly, a map trace feature than visually shows the path of the ECU reading the map. I can explain further if need be, this feature is present both on the haltech software and NIStune also.

The blue line in this picture is a short map trace on Haltech software:

I hope these are helpful, love the system so far!

Thanks,

Hayden

New EMU owner here from Australia.

Not sure if these things have been mentioned already, but a few feature requests for the software:

- Ability to change units(Load in PSI or KPa for example)

- A gauge for MGP (manifold gauge pressure) rather than MAP only

- Ability to use MGP value on the table load axis rather than MAP only

- Different gauge layouts, just simple text box type so they can be made smaller on the desktop page and still easily be read to grab value whilst tuning. This is a screen cap from my haltech layout and my NIStune layout, which I use 90% of the time I am tuning. The gauges are great on their own desktop, but I find them very hard to read in small size. This could also be done by making each gauge with a context menu that allow setting gauge type, for exmaple: Bar Gauge, Text Gauge, Dial Gauge, Graph Gauge etc... Then a propertied window where you could set warning values, colors etc.

- Min/Max values for each gauge, and when that threshold was met, the gauge would flash red or similar. Haltech software works this way and it is very handy for seeing when CLT for example is oevrheating on the dyno as the red flashing grabs attention. Same with Oil Pressure dropping below a minimum.

- Lastly, a map trace feature than visually shows the path of the ECU reading the map. I can explain further if need be, this feature is present both on the haltech software and NIStune also.

The blue line in this picture is a short map trace on Haltech software:

I hope these are helpful, love the system so far!

Thanks,

Hayden

Re: Bugs and Feature reqests

Feature request

Hi

would it be possible to have a table to allow different kill times for the flatshift function based on gear (currently calculated from VSS)

in my dragbike application i have a modified transmision that will shift from 1st to second without needing an ignition kill

all other gears still need the kill function

thanks

Hi

would it be possible to have a table to allow different kill times for the flatshift function based on gear (currently calculated from VSS)

in my dragbike application i have a modified transmision that will shift from 1st to second without needing an ignition kill

all other gears still need the kill function

thanks

Re: Bugs and Feature reqests

Hi Haydenoneten wrote:Hi Guys,

New EMU owner here from Australia.

Not sure if these things have been mentioned already, but a few feature requests for the software:

- Ability to change units(Load in PSI or KPa for example)

- A gauge for MGP (manifold gauge pressure) rather than MAP only

- Ability to use MGP value on the table load axis rather than MAP only

- Different gauge layouts, just simple text box type so they can be made smaller on the desktop page and still easily be read to grab value whilst tuning. This is a screen cap from my haltech layout and my NIStune layout, which I use 90% of the time I am tuning. The gauges are great on their own desktop, but I find them very hard to read in small size. This could also be done by making each gauge with a context menu that allow setting gauge type, for exmaple: Bar Gauge, Text Gauge, Dial Gauge, Graph Gauge etc... Then a propertied window where you could set warning values, colors etc.

- Min/Max values for each gauge, and when that threshold was met, the gauge would flash red or similar. Haltech software works this way and it is very handy for seeing when CLT for example is oevrheating on the dyno as the red flashing grabs attention. Same with Oil Pressure dropping below a minimum.

- Lastly, a map trace feature than visually shows the path of the ECU reading the map. I can explain further if need be, this feature is present both on the haltech software and NIStune also.

The blue line in this picture is a short map trace on Haltech software:

I hope these are helpful, love the system so far!

Thanks,

Hayden

Interesting you raise the points about the gauges i have also mentioned this before, to display in a digital format would be very handy, but bar slider display is also a good format thats very easy to read in a compact size. I also agree that to display +/- PSI for VE and boost tables, gauges, map, oil/fuel/boost pressure etc etc, would be an easy and familiar format for many of us to work with.

There is already an alarm/ redline for the gauges where it flashes red etc, but its a bit hard to find its in the logging setups and it only has a single set point with alarm above or below not 2 set points, a right click on the gauge itself would be very handy to set up all these options.

-rama

Re: Bugs and Feature reqests

Software/Datalog freezing above 5,000rpm: Fixed.

Just wanted to update on an issue I have been having where everytime I try to data log and stray above 5,000rpm my software freezes.

I tried numerous toughbook laptops, numerous USB cables etc and always as soon as I hit somewhere around 5,000rpm the software/log would freeze.

Yesterday I tried an expensive USB cable designed for high data speed and for the first time ever I have a complete log with no freezing.

I believed I had ruled out the USB cable but clearly not.

I hope this helps anyone else in the future who may have a similar issue as it makes tuning in the high rpm almost impossible.

Edward.

P.S The Keelog serial data logger still does not record AFR/Lambda target so can not be used for autotune.

Just wanted to update on an issue I have been having where everytime I try to data log and stray above 5,000rpm my software freezes.

I tried numerous toughbook laptops, numerous USB cables etc and always as soon as I hit somewhere around 5,000rpm the software/log would freeze.

Yesterday I tried an expensive USB cable designed for high data speed and for the first time ever I have a complete log with no freezing.

I believed I had ruled out the USB cable but clearly not.

I hope this helps anyone else in the future who may have a similar issue as it makes tuning in the high rpm almost impossible.

Edward.

P.S The Keelog serial data logger still does not record AFR/Lambda target so can not be used for autotune.

Re: Bugs and Feature reqests

Hi,

TPS vs RPM under fuelling actually shows MAP instead of TPS, and whilst logging it is actually referencing MAP instead of TPS.

Also would it be possible to add a TPS vs RPM under Ignition?

Thanks,

Edward.

TPS vs RPM under fuelling actually shows MAP instead of TPS, and whilst logging it is actually referencing MAP instead of TPS.

Also would it be possible to add a TPS vs RPM under Ignition?

Thanks,

Edward.

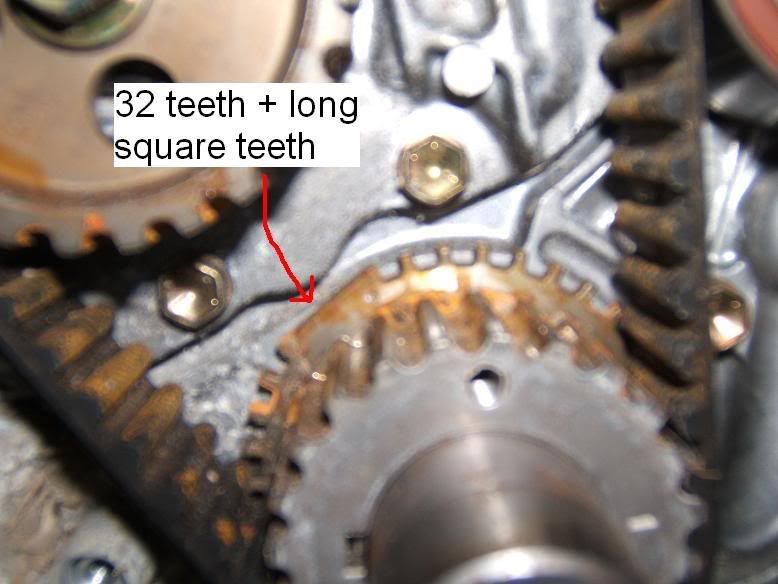

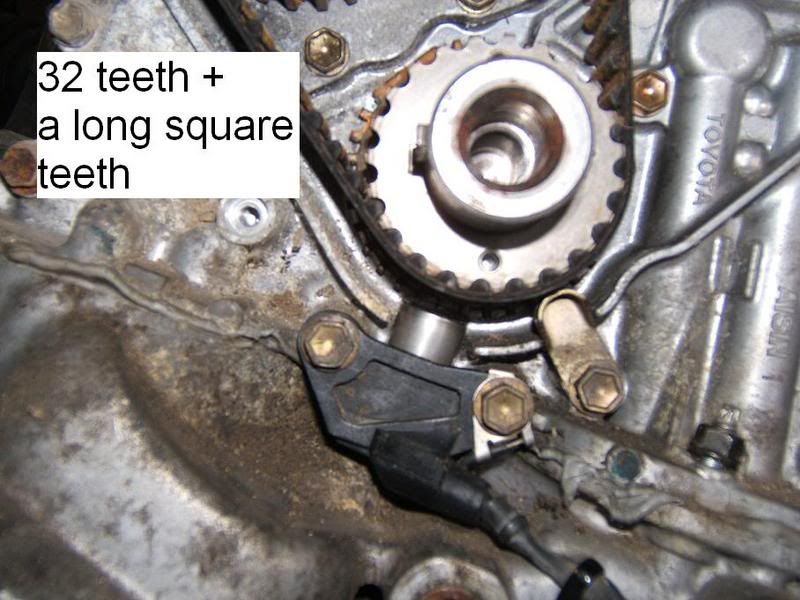

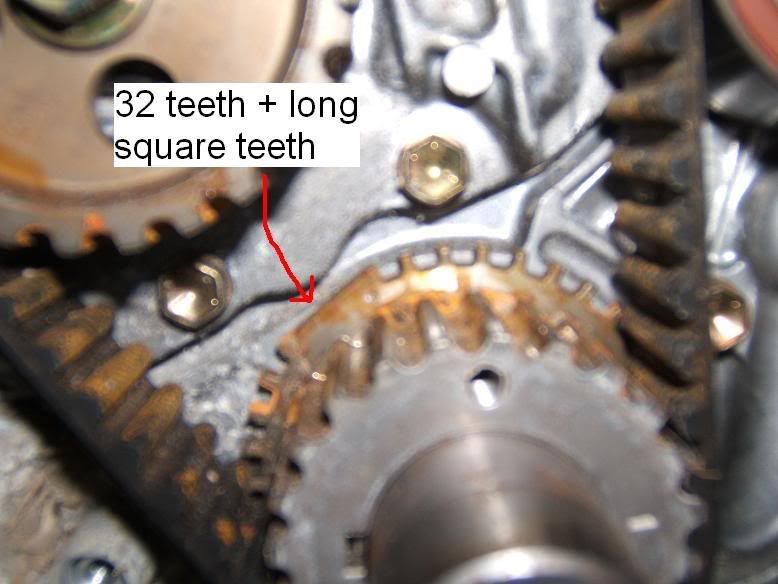

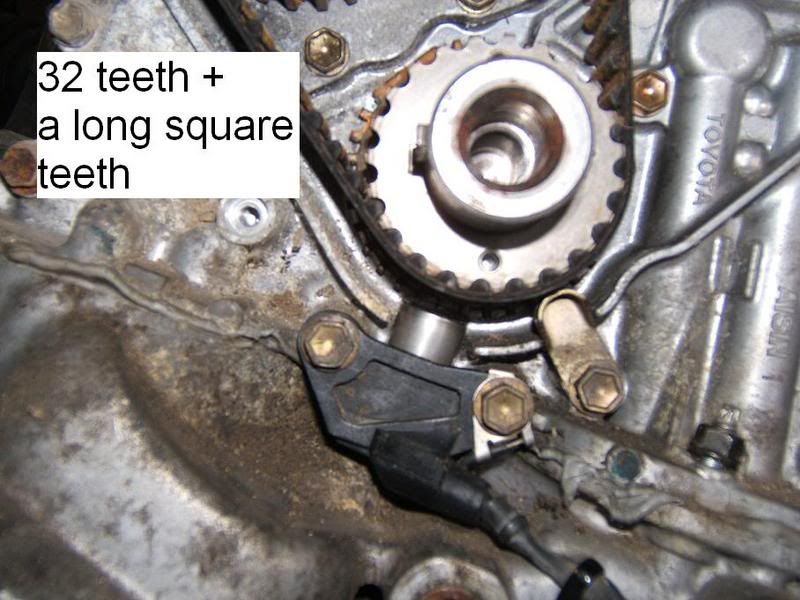

Re: Bugs and Feature requests

It seems that 36-4 trigger pattern is not supported?

The engine in question is toyota 3S-GTE gen 4, crank trigger photos attached.

Can i use "toothed wheel with additional tooth" pattern, and set it like it has 32 teeth and additional one?

The engine in question is toyota 3S-GTE gen 4, crank trigger photos attached.

Can i use "toothed wheel with additional tooth" pattern, and set it like it has 32 teeth and additional one?